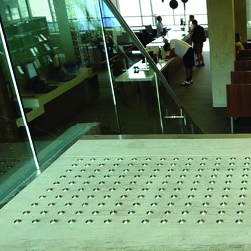

In areas experiencing relentless footfall daily, like transit terminals or commercial complexes, lesser durable tactile solutions simply won't suffice. Heavy usage translates to intensive abrasion that can quickly degrade standard products, compromising safety compliance. Fortunately, advanced heavy-duty tactile options exist catering precisely to zones enduring punishing traffic loads.

As per Canadian accessibility codes, tactile surfaces known as tactile walking surface indicators (TWSIs) must be installed in some public zones. TWSIs alert pedestrians, especially those with vision loss, about hazards or guide routes through texture. Common TWSI types are:

Truncated Domes: Warn of drop-offs or stairs through raised bumps as per CSA B651

Bars: Provide directional cues along paths of travel indicated by parallel raised lines

When specified properly, TWSIs empower independent navigation. However, the material choice depends on usage - light-traffic areas suffice with standard polymers, but heavy zones demand robust metals.

Footfall affects product longevity. Zones like those below see phenomenal 24/7 usage, warranting exceedingly durable TWSIs:

Transit Centers: Bear millions of daily commuters

Shopping Malls: Experience avalanches of foot traffic

Stadiums: Accommodate crushing crowds

Airports: Transport staggering passenger volumes

Office Towers: Concentrate workday Movement

Industrial Plants: Endure shifts of worker movement

Lesser products would deteriorate promptly here through constant abrasion, compromising safety. Specialty heavy-duty options optimize longevity even in punishing conditions.

As per our previous blog, not fulfilling accessibility mandates like proper TWSI installation carries grave liability per Canadian accessibility laws such as the Accessibility for Ontarians with Disabilities Act (AODA).

Non-compliance in busy zones escalates risks multifold due to amplified chances of accidents from degraded, non-compliant indicators. Costly lawsuits, fines, and corrective works can be avoided through properly specified tough tactile solutions.

Let's examine popular heavy-duty TWSI material options verified to withstand relentless footfall:

Corrosion resistance withstands harsh conditions beyond polymer lifetimes

Strength endures truck/vehicle loads without damage

Slip-resistant even after decades of use

High compressive strength bears unimaginable static/dynamic loads

Durability handling impact/indentation better than other materials

Surface enduring decades of heavy abrasive traffic

Hardness and density avoid degrading under the busiest usage

Slip resistance maintained despite damage or wear over the lifetime

Aesthetics suit lobbies/concourses, complementing interior/exterior designs

Engineer elastomers/composites optimizing mechanical properties

Compounds resist weather, moisture, impact, and corrosion better than standard polymers

Reinforced with ceramic/micro glass improve longevity multi-fold

Given their extraordinary strength and longevity, these robust TWSI options from suppliers like Tactile Solution Canada are codified for areas enduring intensive traffic:

Proper specification based on local codes delivers performance-tested, code-compliant accessibility even in the busiest locales.

With estimated 5+ year product lifecycles under standard usage, extreme traffic halves longevity. Maintaining TWSI integrity demands commitment from managers through:

Periodic access audits by outside experts to proactively identify degradation

Establishing TWSI replacement schedules tailored to each locale's specific usage

Budgeting tactile asset management as standard facility operational cost

Training cleaning/maintenance staff in gentler procedures safeguarding textures

Blocking off zones during replacements to avoid temporary non-compliance risks

Consulting TWSI suppliers like Tactile Solution Canada routinely for stewardship best practices

Diligent stewardship preserves unhindered accessibility through replacement ahead of looming non-compliance from wear, upholding welcome and safety.

A: Under extreme conditions, robust metal options like stainless steel or cast iron can withstand 15-25 years of heavy usage before requiring proactive replacement.

A: No, intensive abrasion would degrade standard polymers within 1-3 years, compromising slip resistance and code compliance. Specialty durable metals or composites are verified to fulfill mandates long-term.

A: Replace tactile preemptively when field inspections note 25-30% loss of original texture/dome heights to preserve slip resistance and standards-aligned performance.

A: Third-party audits through accredited professionals help validate that tactiles still meet all applicable codes and remain fit for purpose in the busiest locales over time through rigorous on-site inspections.

By properly specifying robust TWSI materials suited for the most punishing conditions and practicing diligent stewardship, welcoming accessibility can reliably endure even in locales experiencing unimaginable footfall volumes daily. Tactile Solution Canada ensures this through expertise in heavy-traffic tactile solutions.