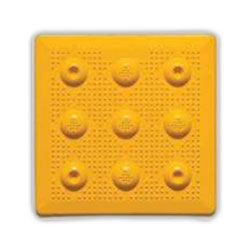

Ensuring safe access for all citizens has become an imperative for builders and managers across Canada. Tactile walking surface indicators (TWSIs) play a vital role in communicating hazards and wayfinding cues to pedestrians with visual disabilities. Among the most versatile TWSI solutions are self-adhesive domes and bars from Advantage Tactile Systems.

Advantage One domes and bars are fabricated from durable stainless steel with slip-resistant textures for indoor and outdoor applications. Their self-adhesive backing enables swift installations on level concrete or tile/stone flooring without drilling. This makes them ideal for retrofitting existing structures or temporarily marking hazards during construction/renovation work.

Advantage One truncated dome and directional bars from Advantage Tactile Systems provide robust stainless steel tactile warning systems that can self-adhere onto existing concrete or asphalt.

These domes and bars feature integral anti-slip textures and are engineered to withstand extremely heavy foot traffic. The self-adhesive backing creates a tenacious yet replaceable bond with the substrate, facilitating straightforward installation.

Advantage One domes and bars find wide use in settings requiring periodic access route modifications:

Construction sites: Mark underground utilities and designate pedestrian separations.

Retrofit projects: Refresh faded indicators without disruptions from drilling/adhesives.

Office floors: Cordon off temporarily carpeted areas or hazardous spills quickly.

Institutional facilities: Securely indicate accessible washrooms/amenities at events.

Streets/plazas: Direct temporary pedestrians safely around closures or work zones.

Transit stations: Guide through platform gap areas or ongoing renovations.

Parks and trails: Mark day-use pathways or special events to avoid substrate damage.

Shopping malls: Cue entrance/exit points during renovations without surface scarring.

With growing accessibility demands, self-adhesive Advantage One dome and bars provide a swift yet code-compliant solution for safely accommodating access requirements.

Advantage One products ship pre-cut and ready for application right out of the box. Certified accessibility installers first layout site templates to delineate placement zones. They then peel protective liners to expose self-adhesive backing on individual domes and bars.

Installation is swift and non-intrusive. Domes and bars are firmly pressed onto the marked substrate with gentle hand pressure. No drilling, layout marking, or mess is involved, minimizing disruptions to pedestrian routes. The tough fiberglass-reinforced backing tenaciously bonds to surfaces on contact.

For enhanced adhesion or on uneven porous floors, a small bead of construction-grade adhesive can be applied underneath indicators. But in most applications, the durable self-adhesive coating alone provides years of reliable bonding. Immediate access is allowed after placement, with no curing downtime required.

Proper surface preparation is vital before installing Advantage One self-adhesive tactile. Key steps include:

The substrate must be clean, dry, and free of oil, grease, dust, curing compounds, loose particles, and projections. Allow fresh concrete to cure for 30 days minimum.

On existing surfaces like old concrete, use pressure washing and detergents to thoroughly clean grime. Rinse and allow to dry completely.

Any surface irregularities should be patched for a smooth finish. Cracks or joints wider than 1/4 inch must have a sealant filler applied.

The installation area must be inspected just before applying tactile to ensure suitability.

These measures allow the self-adhesive tiles to form a tenacious, long-lasting bond with the substrate.

Follow step-by-step procedures to install the self-adhesive truncated domes properly:

Position Template and Mark Layout: Place the manufacturer-supplied dome template in the desired location and orientation. Tape securely. Use a permanent marker to outline the dome profile per the specified spacing/grid pattern on the substrate.

Thoroughly Clean Surface: Sweep and wipe inside the marked area to clear dust or debris. Prepare a clean surface for the adhesive to bond effectively.

Apply Domes: Peel off the dome's release liner to expose the adhesive. Firmly press the dome into place by hand or with a rubber mallet, applying even pressure on the top flat surface. Apply adequate pressure for 10 seconds until the adhesive makes full contact with the substrate.

Repeat for Other Domes: Follow steps 2-3 to apply all domes as per the marked layout. Ensure proper alignment between domes.

Roll Entire Area: Once all domes are affixed, roll over the entire installation area with a hand roller or weighted floor roller to ensure strong, consistent adhesion across the system.

Avoid Traffic for Cure Time: Prevent foot traffic over the installed domes and allow the adhesive to cure adequately as per manufacturer instructions, generally 24 hours at 70°F.

Advantage One self-adhesive domes are now installed and ready to provide critical hazard warnings and navigation cues to pedestrians.

Follow similar procedures to install self-adhesive directional bars properly:

Mark Layout: Place the directional bar template and tape securely. Use a marker to outline the desired pathway orientation for the bars to guide pedestrian travel.

Clean Mounting Surface: Sweep and wipe the marked area to remove any dust or debris for clean adhesion.

Apply Bars: Peel off the release liner on the self-adhesive bar. Press the bar firmly into place along the marked path outline. Use even hand/mallet pressure for strong adhesion.

Roll Entire Area: After affixing all bars, roll the complete installation area with a hand roller or weighted roller for uniform adhesion.

Let Adhesive Cure: Avoid foot traffic over the bars for the recommended adhesive cure time per the manufacturer, generally 24 hours at 70°F or above.

The directional bars can now provide reliable wayfinding guidance once fully cured.

Ensure proper safety protocols during Advantage One tactile installation:

Wear cut-resistant gloves when handling metal domes or bars to avoid sharp edge cuts.

Use safety goggles, boots, hard hats, and high visibility vests as per site regulations.

Follow all applicable government and industry standards for workplace safety.

Install tactile only after surface preparation steps are complete to avoid slips or falls.

By following safety guidelines, the risks of potential injuries can be minimized for installers.

Advantage One truncated domes and directional bars are engineered for extreme durability with minimal maintenance needs. However, follow these practices:

Avoid painting or coating the products, as it reduces slip resistance.

Inspect annually and replace damaged pieces to sustain compliance.

Clear leaves, debris, and dirt promptly to maintain visibility.

Use clean tactile using non-abrasive brushes and avoid corrosive degreasers.

Remove snow carefully without damaging metal.

Proper installation and care ensure Advantage One tactile warning systems maintain compliance and effectively promote accessibility over decades of use.

Installing Advantage One truncated domes and directional bars properly is key to enabling years of optimal performance and safety benefits compliant with ADA/CSA standards. By following recommended surface preparation, step-by-step installation, safety guidelines, and maintenance best practices, you can actualize the full potential of these robust tactile solutions. Contact the experts at Tactile Solution Canada now for any product or installation support needed for your next public realm project.